For Airliners, Cargo Ships, Nuclear Power Plants This Could Be a Game Changer

This new technology provide the exact same characteristics of the traditional steel making process and it is far less expensive. Although this is a great step forward printing steel needs to be investigated further. To maintain a consistent product is difficult with steel because of various cooling temperatures.

Here is a great article in NIST National Institute Of Standards and Technologies

For airliners, cargo ships, nuclear power plants and other critical technologies, strength and durability are essential. This is why many contain a remarkably strong and corrosion-resistant alloy called 17-4 precipitation hardening (PH) stainless steel. Now, for the first time ever, 17-4 PH steel can be consistently 3D-printed while retaining its favorable characteristics.

A team of researchers from the National Institute of Standards and Technology (NIST), the University of Wisconsin-Madison and Argonne National Laboratory has identified particular 17-4 steel compositions that, when printed, match the properties of the conventionally manufactured version. The researchers’ strategy, described in the journal Additive Manufacturing, is based on high-speed data about the printing process they obtained using high-energy X-rays from a particle accelerator.

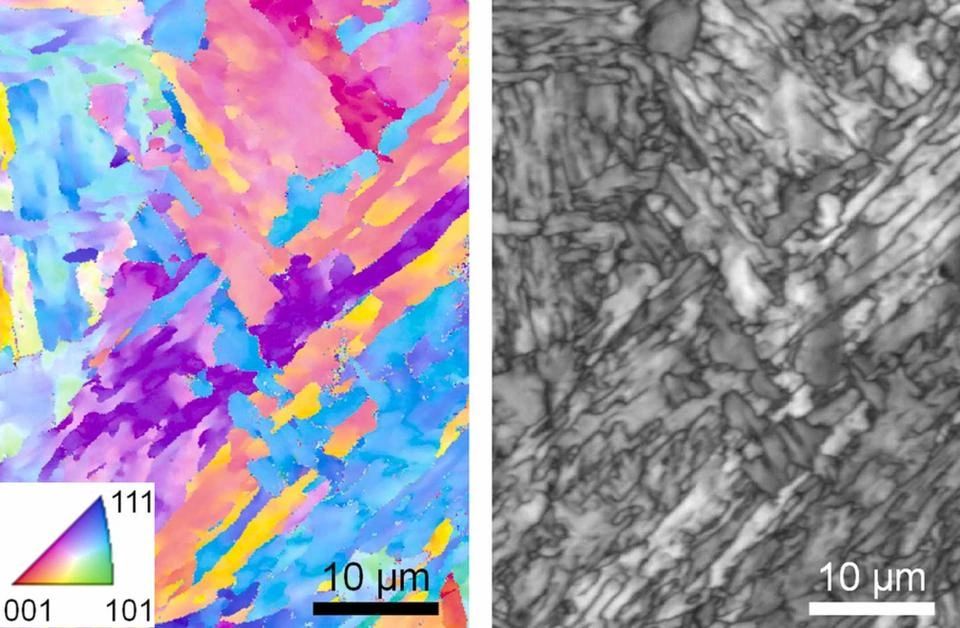

Just as a high-speed camera is needed to see a hummingbird’s flapping wings, the researchers needed special equipment to observe rapid shifts in structure that occur in milliseconds. They found the right tool for the job in synchrotron X-ray diffraction, or XRD.

“In XRD, X-rays interact with a material and will form a signal that is like a fingerprint corresponding to the material’s specific crystal structure,” said Lianyi Chen, a professor of mechanical engineering at UW-Madison and study co-author.