Iron Mikes Explains Kerf When Cutting Or Drilling Steel

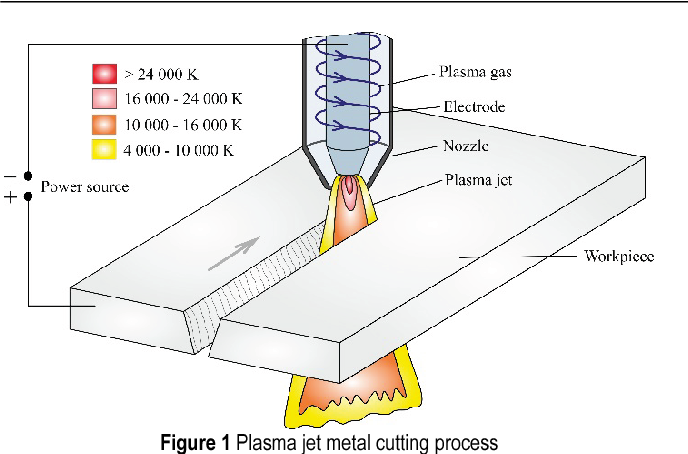

Kerf is the width of a cut made in a sheet of metal. It is the amount of material that is removed when cutting, usually with a saw or laser. The kerf is important to consider, as it affects the dimensions of the finished product. The wider the kerf, the larger the gap in the finished piece.

Additionally, the wider the kerf the more material is wasted. This should be taken into account when designing a project, as it can impact the cost and quality of the finished product. For precision cutting, a narrow kerf is ideal. This ensures that the finished product is as close to the desired dimensions as possible, while minimizing material waste.

Kerf is the amount of material that is removed from a piece of material when it is cut. When cutting steel, the kerf is the width of the cut made by the saw blade. It is important to take into account the kerf when calculating the amount of material needed for a project.

Too narrow a kerf can cause the blade to bind, while too wide a kerf can waste material and lead to inaccurate results. The kerf of a saw blade is typically specified in the product specifications and should be taken into account when selecting the saw blade for a particular project.