Its All In The Temperature It Is Made At

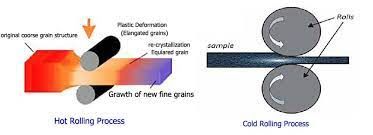

Hot rolled steel and cold rolled steel are both produced at a steel mill and can be formed into coils or sheets. The main difference between the two is the temperature at which they are formed.

Hot rolled steel is formed at a high temperature, around 1700°F (926°C), which is above the recrystallization temperature of steel. As a result, it is easier to work with, and the steel can be shaped and formed more easily. Hot rolled steel is typically used in applications where the finished product does not require precise shapes or tight tolerances. It is also used in the production of structural components, such as beams and sheets, as well as in the construction industry for the production of rail tracks and other infrastructure.

Cold rolled steel, on the other hand, is formed at a much lower temperature, around 700°F (371°C). This process makes the steel more workable and gives it a better surface finish. Cold rolled steel is typically used in applications where precise shapes and tight tolerances are required, such as in the production of automotive components and machinery parts. It is also used in the production of steel sheets and strips, which are then used in a variety of applications, including construction, appliances, and automotive parts.

In summary, hot rolled steel is formed at a high temperature and is typically used in applications where precise shapes and tolerances are not required, while cold rolled steel is formed at a lower temperature and is used in applications where precise shapes and tolerances are required.