How is Steel Made ? Old Cartoons Make It Easy To Understand

This Cartoon From Sustainable Steel , WorldSteel. 2012, demonstrates the sustainability of steel. We have come a long way in steel production since then with automationand technology. Even though we have more technology it is still as basic as the image above.

In all the years I have been in the steel industry It is still so fascinating how steel is made and how energy such as heat creates steel. It is the first step in creating anything from a surgical instrument to an aircraft or even an aircraft carrier.

How is steel made?

Steel production involves three main stages:

- Preparing raw materials (coking)

- Ironmaking

- Steelmaking

Preparing raw materials – Coal is heated in an oxygen-free environment to create coke, a carbon-rich fuel which is responsible for a large portion of emissions from steel production.

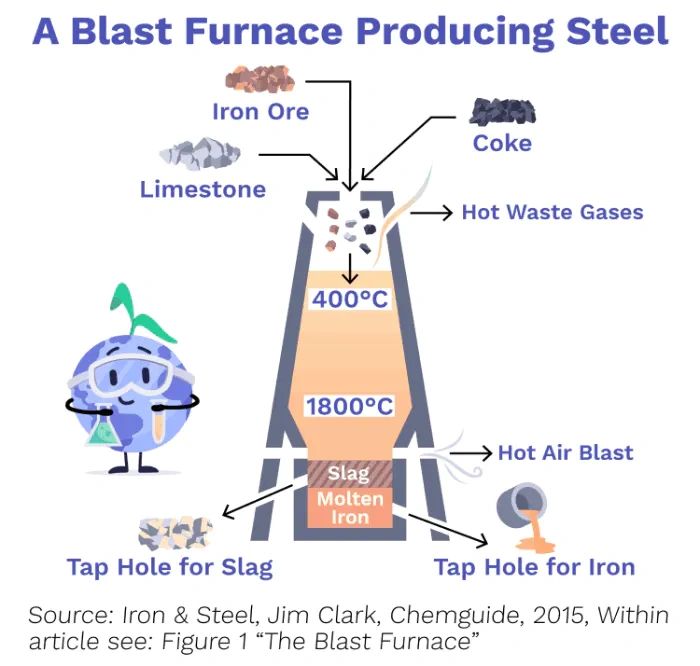

Ironmaking – Coke is heated in a blast furnace along with limestone and iron ore. The limestone removes impurities and is turned to ‘slag’ while the iron ore is reduced into molten iron. Reduction in this case involves removing oxygen and adding hydrogen to the ore.

Steelmaking – Finally, impurities are removed from the molten iron to create steel.

Newer methods are more efficient but still based on those same three stages. Using these stages there are two main ways to produce steel:

1. Blast Furnace – 70% of all steel is produced this way. It uses molten iron ore as the starting material and coke as the reducing agent.

2. Electric Arc Furnaces (EAF’s) – these produce 25% of all steel. Here, recycled steel is used as the starting material. Compared to blast furnaces, these furnaces are smaller and don’t need coke as a reducing agent (as they use electricity to melt the iron ore), so they produce much less CO₂. They’re also cheaper to run than blast furnaces!

Hope this was helpfull. great article from World Steel in 2012!!